What Is Plastic Concrete Formwork? What Do Plastic Concrete Formwork Do?

What Is Concrete Formwork?

Concrete is a crucial and basic construction material in building industry. Formwork plays an important role in assisting geometry realization and strength development of concrete elements. It is also one of the major costs in the construction of concrete structures. The use of formwork has a long history, and various formwork systems have been used in different projects. In the design and selection of formwork system, the requirements, such as safety, cost, structural geometry, construction time and surface quality need to be taken into account.

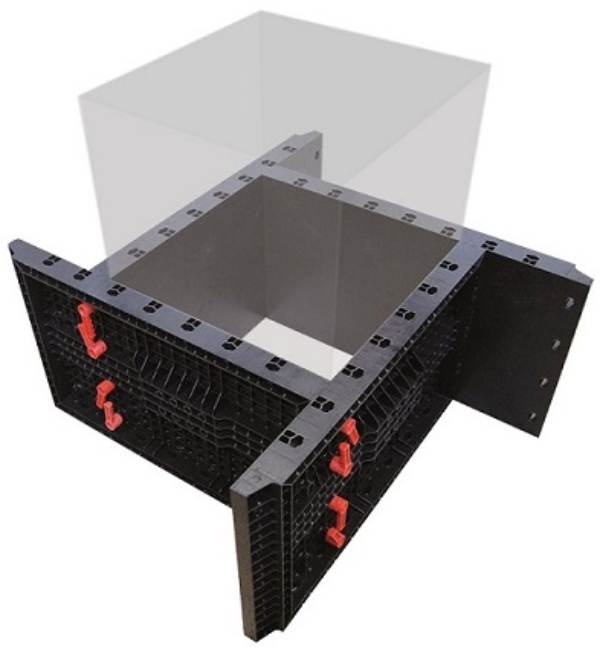

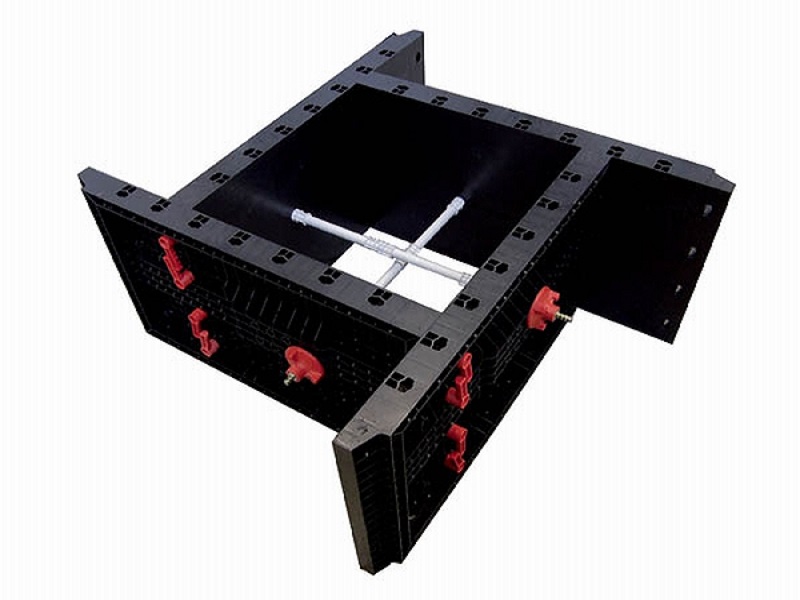

Column formwork is specially produced for range and adjustable Column with many sizes in building project. as you know dimensions of coulmn is reduced while the building go higher. For example in a 10 stories bulding , if the size of column formwork in first story was 100x100 cm you're more likely to have 60x60 cm Column dimension in 10th story. So, have adjustable Plastic column formwork can help to optimize the need to buy plastic formwork or steel formwork.

Zagros Plastic Formwork offers various plastic formwork systems in forming fresh Concrete like Plastic Formwork System, Plastic Waffle Slab Forms, Plastic Ribbed Slab Formwork, Rubbish Chute System, Hollow Plastic Sheets, including their raw materials, flexibility, fabrication methods, applications in concrete structures and environmental impacts.

What is the Price of plastic concrete Formwork Panels?

As you know in construction sector and all types of industry, the first and foremost factor for doer and contractors is Price. The most important factor in plastic concrete formwork price is the type of raw material whether ABS polymer or something else. The mechanical characteristic of ABS material is so wild and if you test it in the civilsite you'll find it so strond and anti-corrosion and long-term usage material.

| Concrete Formwork Size |

Weight (Kg) |

Price ($) |

| ABS 120x60 cm |

10.5 |

28 |

| ABS 40x60 cm |

3.6 |

10.2 |

| ABS 35x60 cm |

3.4 |

9.6 |

| ABS 30x60 cm |

3 |

8.5 |

| ABS 25x60 cm |

2.6 |

7.5 |

| ABS 20x60 cm |

2.2 |

6.5 |

| Inner Corner |

4 |

11 |

| Outer Corner |

3.3 |

9.2 |

| Column formwork 60x60 cm |

6.8 |

19 |

| Column formwork 65x60 cm |

7.2 |

21 |

| Complete Column with height 3 meter and 60x60 cm dimension |

150 |

510 |

| Complete Column with height 3 meter and 65x65 cm dimension |

170 |

540 |

Zagros Plastic Concrete formwork system is new kind of modular concrete formwork system or Largepanels plastic concrete Formwork which recently take attraction in construction industry. Due to light weight and fast-locking design handles can be carried out easily by single person. Because of light weight, do not need to have tower crane for moving in projects especially villa projects and building structures. Plastic concrete formwork is a new generation of modular concrete formwork (Modular Plastic concrete Formwork System) for walls and columns, which, due to their lower weight compared to steel concrete formwork, high strength and ease of work, leads to high project speed. The primary material for the production of plastic concrete formwork (modular polymer concrete formwork) can be polyethylene polymer (PE), polypropylene polymer (PP) and ABS polymer.

Cost of Plastic Formwork for Concrete Structure:

Price of each square meter of plastic concrete formwork from virgin ABS material with all handles is around $50 and if the material turn to recycle PP the price for each sqm will be $25.

Each type of raw material in the production of plastic concrete formwork (Plastic Concrete Formwork) has its own advantages and advantages, which will be discussed further below about the effect of raw materials and polymers on plastic concrete formwork.

Zagros Plastic Concrete Formworks (ZagrosForm) and shuttering stuffs are made up of high quality ABS or PP (PolyPropylene) with flexural-enhanced material. Our construction plastic concreet formwork has been designed to create smooth and exposed concrete surface for finished layer. Hence aesthetically pleasing surface would be expected by using plastic concrete formwrok system. Non-stick feature of polymer which turns to not adhere concrete to them is main reason for last-long and durability of plastic concrete formwork.

Weight of each square meter of Zagros plastic concrete Formwork?

The weight of each square meter of plastic concrete formwork is around 14 kg in comparison to 40 to 45 kg for traditional steel concrete formwork . With this in mind, safety is top priorities in construction project so because of its easy to handle, the accident in worksite will goes down to have safer sites for our workforce.

What is the Price of plastic concrete Formwork Panels?

As you know in construction sector and all types of industry, the first and foremost factor for doer and contractors is Price. The most important factor in plastic concrete formwork price is the type of raw material whether ABS polymer or something else. The mechanical characteristic of ABS material is so wild and if you test it in the civilsite you'll find it so strond and anti-corrosion and long-term usage material.

| Concrete Formwork Size |

Weight (Kg) |

Price ($) |

| ABS 120x60 cm |

10.5 |

28 |

| ABS 40x60 cm |

3.6 |

10.2 |

| ABS 35x60 cm |

3.4 |

9.6 |

| ABS 30x60 cm |

3 |

8.5 |

| ABS 25x60 cm |

2.6 |

7.5 |

| ABS 20x60 cm |

2.2 |

6.5 |

| Inner Corner |

4 |

11 |

| Outer Corner |

3.3 |

9.2 |

| Column formwork 60x60 cm |

6.8 |

19 |

| Column formwork 65x60 cm |

7.2 |

21 |

| Complete Column with height 3 meter and 60x60 cm dimension |

150 |

510 |

| Complete Column with height 3 meter and 65x65 cm dimension |

170 |

540 |

Quick Comparison of All Types of Concrete Formwork:

Comparison of Plastic Concrete Formwork, Steel Concrete Formwork and Plywood Concrete Formwork:

| item |

Plastic concrete Formwork |

Traditional Formwork |

Steel Formwork |

| money return from purchasing broken formwork after Usage |

40% |

No |

10% |

| Water Resistant |

Yes |

No |

No |

| Deformation Condition |

No |

Yes |

Yes |

| Stripping Process |

Easy |

Moderate |

Difficult |

| Size |

Any size can supply |

Restricted |

Any size can supply |

| Corrosion resistant |

Excellent |

Bad |

Bad |

| Available Item |

More than 100 times |

10 times |

100 times

|

Different Types of formwork shuttering system

When it comes to types of material for plastic injection for producing plastic Panels formwork, we have two options :

- Raw Material such as ABS, PolyPropylene (PP) and Poly Ethylene (PE)

- Recycled Material (recycled PP or ABS)

Plywood or Metal Formwork could be replaced completely with Plastic Panels and plastic panels are eco-friendly and environmental friendly choice. The expectation is to use them more than 100 times and then can be recycled plastic panels and produce the recycled ones.

Advantages of Plastic Formwork System For Columns and walls:

- Light weight, Rigid, Strong, Durable, Waterproof, Moisture-proof

- Chemical resistace, Anti-impact and fade, Anti-folding, Anti-Aging, High flexural strength properties

- Easy to fabricate, Custom size, Non-toxic

- Corrosion-resistanct, Finished sufrace of concrete wall, columns or slab will be gorgeous, rich in quality, Odorless

- Environmental friendly. Recyclable, Washable with water,

ABS Plastic concret Formwork Price :

Let's start with Size of Plastic Panels we provide and also prices of each panels:

To comparison plastic formwork system with traditional formwork and metal (Steel) formwork, we provide a table for detailed comparison :

Two Types of Plastic Formwork system :

Concrete plastic formwork are produced and supplied in two general types and shapes:

1) Plastic concrete formwork with thickness of 5 cm:

This type of concrete plastic formwork has the ability to be compatible and paired with the concrete steel formwork, and therefore this type of concrete plastic formwork can be easily paired with the concrete steel formwork. The tools for closing the concrete plastic formwork with a 5 cm edge are the same pins and wedges used in the concrete steel formwork.

:These plastic concrete formworks is now available in below sizes

- 100x50 cm

- 100x40 cm

- 100x35 cm

- 100x30 cm

- 100x25 cm

- 100x20 cm

- 100x15 cm

- 100x20 cm

2) Concrete plastic formwork with thickness of 8 cm:

which is known as the Italian concrete plastic formwork.

The weight of each square meter of concrete plastic formwork is around 14 kg, which is much lighter compared to the weight of 45 kg per square meter of concrete steel formwork. It is obvious that the lighter the weight of the concrete plastic formwork, the higher the execution speed and the safety and fatigue of the workforce is reduced.

On the other hand, due to the low weight of these concrete formworks, it is possible to load 300 square meters of these concrete formworks in a 5.5-meter truck. Concrete plastic formwork are produced in different dimensions other than concrete steel formwork. The height of concrete plastic formwork is 60 cm and they are designed and produced in different lengths from 20 cm to 120 cm.

Sizes of concrete plastic formwork

Modular concrete plastic formwork are produced and supplied in different dimensions.

concrete plastic formwork 120x60 cm: This plastic concrete formwork is called (BP120) which has a length of 120 cm and a height of 60 cm.

concrete plastic formwork 20x60 cm: This plastic concrete formwork is called (BP20) which has a length of 20 cm and a height of 60 cm.

concrete plastic formwork 25x60 cm: This plastic concrete formwork is called (BP25) which has a length of 25 cm and a height of 60 cm.

concrete plastic formwork 30x60 cm: This plastic concrete formwork is called (BP30) which has a length of 30 cm and a height of 60 cm.

concrete plastic formwork 35x60 cm: This plastic concrete formwork is called (BP35) which has a length of 35 cm and a height of 60 cm.

concrete plastic formwork 40x60 cm: This plastic concrete formwork is called (BP40) which has a length of 40 cm and a height of 60 cm.

Inner Corner concrete plastic formwork: This plastic concrete formwork is called (BPIN) which has a length of 30 cm and a height of 60 cm.

Oter Corner concrete plastic formwork: This plastic concrete formwork is called (BPOUT) which has a length of 25 cm and a height of 60 cm.

Again, to the dear readers of this article, I would like to say that all the concrete plastic formwork produced by Zagros Sanat Beton Company have a height of 60 cm, and when it comes to the BP20 concrete formwork, for example, the number 20 represents the length of that concrete formwork, that is, 20 cm. The height of this concrete formwork is 60 cm.

Adjustable Plastic Columns Formwork System:

The column concrete plastic formwork produced in Zagros Concrete Company are considered to be an interesting and attractive light source in this field. concrete plastic formwork columns are produced in two sizes:

1- Column concrete plastic formwork 60x60 cm:

This column format is called BPS2060, which has a length of 60 cm and a height of 60 cm. Price of concrete plastic formwork is around $50/sqm for ABS material and for PP material is around $20/sqm.

By purchasing a set of Column formwork that includes 20 column concrete formworks with 150 levers. With these 20 plastic column concrete formworks, all column dimensions from 20x20 cm to 60x60 cm can be concreted. The point to be mentioned in this case is the weight of this plastic column, the whole concrete formworks and accessories of this column weigh about 145 kg, which is not comparable to a metal column of the same size. Therefore, in villa construction projects where the use of a crane is a challenge, it is a very suitable option for the implementation of foundation, wall and slab.

Due to the ability of concrete plastic columns formwork to be adjusted, there is no need to use zero corners, 10 and 5 cm corners. For example, if the employer needs to cover a 60x50 cm column using plastic column concrete formworks, it is enough to put one side or one side of the column panels on the 60 cm number and the other side and the other side on the plastic concrete formwork. Set it to 50 cm, and then the desired column will be formatted.

From the right side, the first concrete formwork, which is a plastic column concrete formwork, which, as mentioned above, has a height of 60 cm, due to the ability of the column concrete formworks to be rigged, one rib has been deducted on the 60 cm column concrete formworks and the concrete formworks on the part 50 cm of the column is closed and the desired plastic column is ready for concreting.

Maybe this question will arise, how will the scaffolding of concrete plastic formwork have to be done?

The simplest answer to this question is that the restraint of these concrete plastic formwork is just like steel plastic formwork and you can use the same double-tube or single-tube gasket with conventional scaffolding pipes or struts made of 40x80 mm box.

2- Column Plastic Formwork panel 65x60 cm:

This column format is called BPS2565, which has a length of 65 cm and a height of 60 cm.

Zagros concrete company has put the exclusive production of these concrete plastic formwork on its agenda since 2008, and the concrete plastic formwork of this company are known under the brand name Zagros Panel (Zagros Panel) in the market of the Middle East and Abroad.

The main feature of Zagros Formwork concrete plastic formwork is the edge thickness of these concrete formworks, which is 8 cm. The concrete steel formwork available in the Iranian market have 5 cm edges. Since the elastic modulus of metal is about 200 GP (GigaPasgal), which is much higher compared to ABS polymer, the edge of plastic concrete formworks should be 8 cm to compensate for this defect of plastic compared to metal.

Recently, in the Iranian market, a 5 cm thickness concrete plastic formwork made of polyethylene has been produced and entered the market. Due to the lack of stiffness with the issues related to the very low modulus of elasticity of polyethylene compared to iron, it has not been able to satisfy the customers need and lead to the pessimism views towards plastic formwork system and polymer formworks.

What is the raw material of concrete plastic concrete formworks or polymer concrete formworks?

When the production of polymer or plastic concrete formworks is on the agenda, three types of petrochemical raw materials can be used:

- Acrylonitrile butadiene styrene polymer (ABS)

- Polypropylene polymer (PP)

- Polyethylene polymer (PE)

With a brief search and examination of the characteristics of the above three polymers, it is easy to see that the mechanical characteristics of the ABS polymer are much higher and stronger compared to the other two polymers. Therefore, Zagros Formwork Sanat produces polymer concrete formworks in two types and characteristics, one with ABS polymer and the other with PP polymer. The price of plastic concrete formworks produced with PP polypropylene polymer is almost half the price of ABS polymer concrete formworks.

What is the main advantage of plastic Fromwork over metal or steel formworks?

- Light weight and ease of implementation and installation due to the weight of one third of these concrete formworks compared to metal concrete formworks

- Due to the light weight, the transportation of plastic concrete formworks is faster and easier

- Due to the insulating nature of plastic, pegplastic concrete formworks can be used in different temperature conditions

- No need for lubrication is one of the advantages of plastic concrete formworks

- Washing plastic concrete formworks with water jet easily makes it possible to increase the useful life of the concrete formworks many times

- ABS plastic Formwork System can be used more than 100 times and the waste of these concrete formworks has 40% of the selling price.

- Considering the waste recycling of these concrete formworks, it can be noted that polymer and plastic concrete formworks are environmentally friendly.

The important and basic questions that are raised at the beginning of the discussion with every construction engineer and contractor in replacing plastic concrete formwork (Concrete Plastic Formwork) with steel concrete formwork (Steel Formwork for Concrete Structures) are the following:

1- How much does each square meter of plastic concrete formwork weigh?

About 13 kg, compared to a metal concrete formwork of about 40 kg per square meter.

2- How much does price of concrete plastic formwork with an 8 cm thikness made of raw ABS not Recycle polymer cost per square meter?

Approximately the same as a steel concrete formwork and about 50 US Dollar. while if they produce from recycle ones the price will be settled in $25 per square meter.

3- How much does a plastic concrete formwork with an 5 cm thickness made of raw polyethylene or PE polymer cost per square meter?

The price of a plastic concrete formwork with a 5 cm thickness is about $ 25 per square meter.

4- In general, how many types of concrete plastic formwork are there on the market?

There are two types of plastic concrete formwork in the market: plastic concrete formwork with an 8 cm edge and a plastic concrete formwork with an 8 cm edge

5- What is the main and fundamental difference between plastic concrete forms?

The main difference should be sought in the design of the blade arrangement behind the formwork, the type of material and raw materials, and the thickness of the edge of the plastic concrete formwork.

6- What is the role of the polymer and raw materials used in the production of plastic concrete formworks?

It can be said that 90 percent of the quality of a plastic concrete concrete formwork for quality and flawless concreting lies in the use of raw materials in accordance with the needs of the customer and the construction project.

7- What is the difference between ABS polymer and polyethylene and polypropylene in Plastic concrete formwork system?

It can be said that polyethylene and polypropylene polymers have nothing to say in the production of plastic concrete concrete formworks compared to ABS polymers, and it is enough to take a close look at the produced sample of plastic concrete concrete formworks made of two types of polymers.

8- Which type of plastic concrete concrete formwork is recommended for the implementation of exposed concrete, faced concrete, and concrete with a very smooth surface?

Without a doubt, using a plastic concrete concrete formwork produced from ABS polymer is the only option for every contractor and engineer to implement exposed concrete.

We produce, from 20 years ago, all type of concrete plastic formwork systems in Walls, adjustable columns and slab as well. When you visit our website. You’ll find two options in concrete plastic formwork systems: panels with body thickness of 8 cm or 5 cm. each panels has its own application and if you need inquiries or piece of information about them, don’t hesitate to contact us via Email, Whatsapp, Telegram or even call.

If your work area is in the remote place, your definitely have no access to crane, and better to reconsider your choice from steel formwork system to plastic formwork systems.

What are the advantages of plastic formwork for concrete?

Due to the perfect production process and use of high quality injection machine, the surface of plastic formworks is like polished and therefore the final surface of your concrete will be exposed without any kinds of spots.

Due to precise injection concrete formwork mould design, the leakage of concrete (ordinary density around 2400 kg/m3) and foam concrete (less than 800 kg/m3 in density) is avoided and you could easily use them for tunnel structural system.

Due to light weight of panels which hardly reach to 13 kg per square meter, it is the most efficient labor-saving system because it is easily and fast in install and move in project sites. In comparison to steel formwork system that has 40 kg per square meter in weight, installation agility and process decreased drastically.

Due to raw material, it is easy recycled and it is evidence for being environmental friendly formwork. Just compare the wood formwork which would have burned at the end of project and the result is deforestation.

Due to plastic-made formwork, evaporation of concrete’s water will be avoided, especially in some countries like Gulf area (KSA, UAE, Oman, Qatar, …) and also in frozen climate this formwork acts as insolation system and keep away the core of concrete from freezing.

Adjustable Columns plastic concrete formwork

Adjustable Columns plastic concrete formwork