Waffle Slab Mold and Waffle Slab

In recent years, due to the updating of the building regulations and the ongoing emphasis of these regulations on roof structure, the removal of "tension zone concrete" has been on the agenda of engineers in the field of structure design. Therefore, the hollow slab (U-boot and Cobiax roofs) and waffle slab (waffle roof) became an attractive option for structural designers.

Main characteristic of waffle slab forms for structural designer is the details of waffle slab mold and its rib width and Height which need to be inserted in Etabs and Safe Software for design.

Waffle Slab mold price for sale

waffle slab forms mainly produce in Two quality: White or black one. As a general rule of thumb the black waffle molds mainly made form recycle material and the White waffles are made from virgin and raw petrochemical polymer. because of that the number of usage for White waffles are doubled than the black waffle molds. if you want to have a number for usage you would consider at leat 25 times for white waffle molds and around 15 -20 times for black.

| Waffle Slab dimension (cm) |

White Waffle form price ($USD) |

Black Waffle Form price ($USD) |

Median Rib Width (cm) |

| 60x60 with Height of 19 cm |

5.5 |

3.4 |

13 |

| 60x60 with Height of 25 cm |

5.9 |

4 |

14 |

| 60x60 with Height of 30 cm |

6.5 |

4.2 |

15 |

| 75x75 with Height of 30 cm |

9 |

6 |

15 |

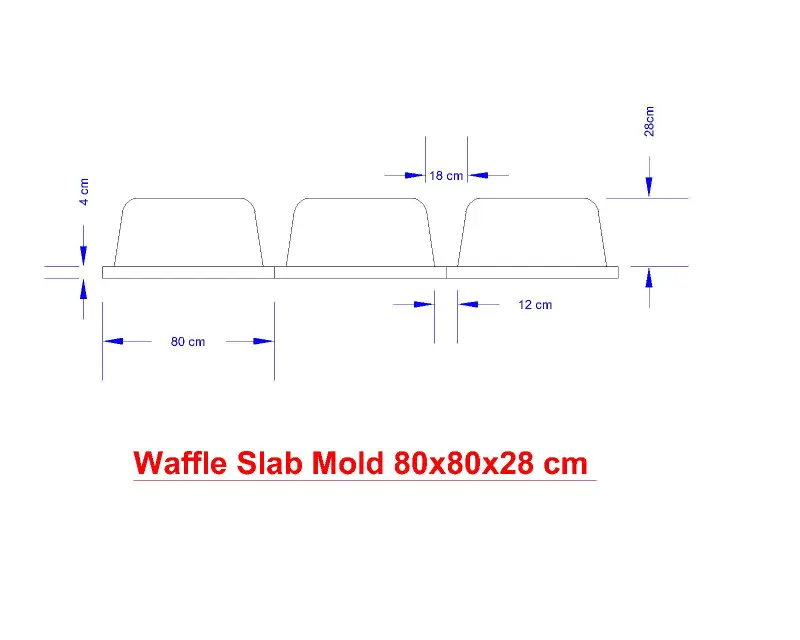

| 80x80 with Height of 28 cm |

9.5 |

6.3 |

15 |

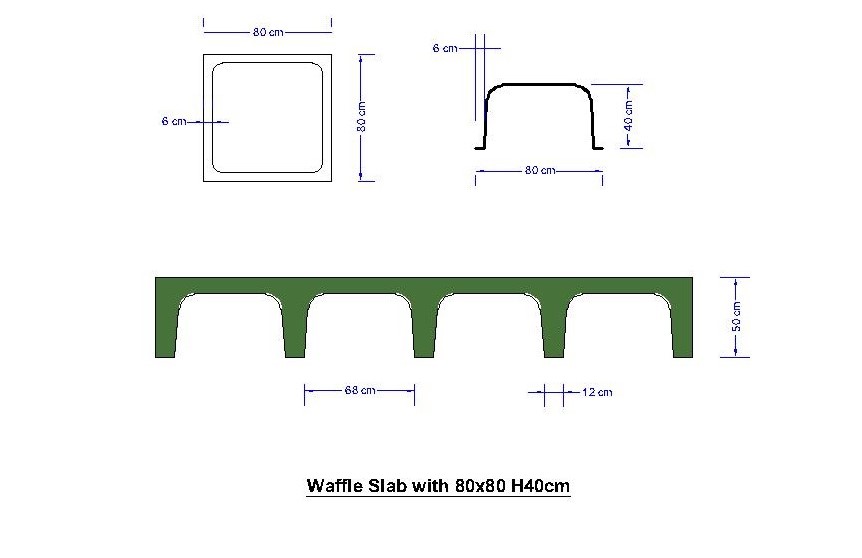

| 80x80 with Height of 40 cm |

12 |

7.9 |

16 |

| 90x90 with Height of 30 cm |

13 |

10.5 |

22 |

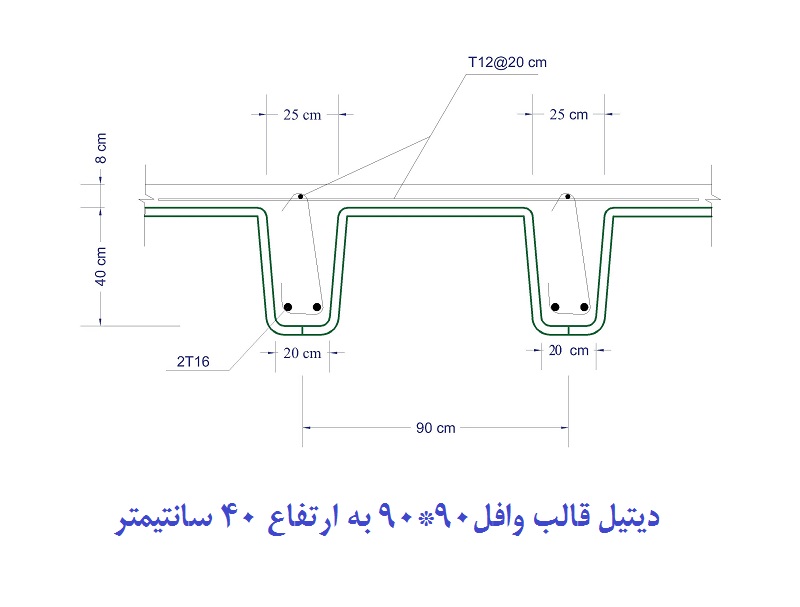

| 90x90 with Height of 40 cm |

14.5 |

11 |

22 |

Under view of waffle slab mold 90*90 with Height of 30 cm for 10 meter column span

Why should we design roof based on Waffle Slab?

The Two-way waffle slab (implemented with a Two-way waffle slab mold) has a special attention among structural designers due to its compatibility with earthquake-prone areas and, most importantly, the recommendation of the American Concrete Code (ACI).

Hollow slabs (U-boot slab and Cobiax Slab) are not an attractive option, at least for earthquake-prone areas, including MiddleEast, due to the lack of transparency of its seismic performance and also the lack of introduction of this type of slab in the American concrete regulations.

The figure below shows the details and specifications of the 60x60 cm waffle slab mold with heights of 25 and 30 cm. In this picture, the plan size of the plsatic waffle slab mold is 60 and the width of the rib (rib width) is specified in this waffle slab mold which is 10 cm.

waffle slab mold of 60*60 cm with height of 30 cm for typical column span of 7 meter

Types of Waffle Slab Forms:

One of the most important points in the correct implementation of the waffle roof is to know the market of various types of waffle molds produced in the country. For example, if the structural designer of the waffle roof conforms to the selection regulations and is also optimal in terms of the consumption of rebar and concrete, but the desired waffle mold is not available in the market, it is not possible to implement that waffle roof. Therefore, it is very important to know the dimensions and sizes of all waffle molds available in the country.

So far, we have realized that knowing the various dimensions of waffle molds available in the market can facilitate the process of choosing a waffle mold and designing. Therefore, the dimensions of the waffle molds produced in Baspar Sanat Concrete Company are as follows:

you see the details of waffle slab form and waffle Formwork of 80*80 with height of 40 cm which is used for over 10 meter column span:

At a glance

The waffle slab mold is divided into two general categories:

1) One-way Waffle Slab mold (Ribbed Slab):

- One-way Waffle slab mold 60 cm with height 25 cm

- One-way Waffle slab mold 70 cm with height 30 cm

2) Waffle slab mold:

- waffle slab mold 60x60 cm in height of 19, 25 and 30 cm

- waffle slab mold 75x75 cm in height of 20 and 30 cm

- waffle slab mold 80x80 cm in height of 28 and 40 cm

- waffle slab mold 90x90 cm in height of 30 and 40 cm

Details of waffle slab mold of 90*90 with height of 30 cm and rib width of 20 cm which is common in use for over 10 meter span

The final view of the waffle slab mold 60 with a height of 25 cm in Shiraz

Executive detail of waffle slab mold (Waffle Slab Form) 60 with height of 25 and 30 cm

1-Details and technical specifications of Two-way waffle mold 60x60 with a height of 25 and 30 cm

Waffle mold substructure with two-sided waffle mold and one-sided waffle mold

2- Two-way waffle slab mold substructure using wooden beams and 3-meter Push-Pull Props

The principles of waffle slab design along with the size of the waffle slab mold:

The engineering vision in the design of the waffle roof with different dimensions of the waffle mold has always been desired by workshop engineers as well as young engineers. The waffle pattern plays an important role in the design of the roof, as well as the column-to-column distance (Span, drop and thickness of the waffle roof). There are various guides for engineers and architects to determine the various parameters of the waffle roof, the most important of which is the overall thickness. Roof (Overall) and Rib Width (Rib Width). This type of structure is a very suitable option for concrete structures that require little vibration, including laboratories and factories If it is higher than usual, such as theaters, subway stations, and trains, the use of waffle roofs and waffle molds should be on the agenda.

The waffle Slab design framework, a thumb account is provided below:

- The thickness of the waffle slab (Slab Depth) is usually in the range of 8 to 13 cm, and in a rule of thumb, the slab thickness should be 0.042 (one twenty-fourth) of the column-to-column distance (Span).

- The width of the beam or rib of the waffle slab mold (Rib Width) is usually considered 12 to 20 cm, and usually two branches of longitudinal rebar grade 18 are placed.

- The height of the appropriate rib and beam for the waffle slab should be equal to 0.042 (one twenty-fourth) of the distance between the columns (Span).

- The dimensions of the column panels around the column should be considered as 0.125 (one eighth) of the distance of the opening. The design of the waffle slab is based on the specifications of the used waffle mold

Advantages of waffle Slab:

- It is very suitable for a building with less vibration, which of course means a two-way waffle mold and as a result, a two-way slab.

- A longer opening with less rebar and concrete is the best way to get it, and it is a more attractive option in terms of economy and environment compared to the solid slab.

- According to some people, the honeycomb form under the ceiling is visually attractive

- Higher load capacity than traditional roofs with one-way operation

- The empty space created by the waffle mold creates a suitable space for the passage of installations, pipes, risers, cables and mechanical and electrical devices.

- The possibility of using the waffle slab molds multiple times, so that if you can buy a waffle mold from Beton Basar Sanat at least 15 waffle roofs with concrete.

Examples of waffle Slab and waffle molds in the world include the following:

- London's National Theater was built in 1963

- Washington subway building built in 1960

- Madrid Communications and Logistics Center

- Galbraith Hall, San Diego, California

The reason for presenting the above examples is to express the fact that the waffle mold and waffle slab have long been built in U.S. and European countries as a superior technique that has shown good performance in the face of earthquakes.

FAQ about waffle slab mold and waffle slab proposal

1- What plastic waffle mold should we use in the project?

In a division, it can be said that 60x60 waffle slab molds are usually used for construction and residential projects with a span length of 7-8 meters, and if the column-to-column distances are greater than these values, then the great option for waffle slab form will be 90*90 cm with height of 30 and 40 cm.

2- What is the difference between waffle slab made from reinforced fiberglass and plastic waffle slab mold with injection molding?

As a general, all parts made by injection molding are far more cheaper than the fiberglass method just because of machinary and less involvment of labor works. waffle slab forms made by injection molding mainly is produced from Polyethelene raw material and really durable and long-term usage than fiberglass waffle slab mold.